"Duck Duck Grey Duck FTMFW!" (theduckduck)

"Duck Duck Grey Duck FTMFW!" (theduckduck)

05/15/2018 at 09:20 ē Filed to: None

0

0

31

31

"Duck Duck Grey Duck FTMFW!" (theduckduck)

"Duck Duck Grey Duck FTMFW!" (theduckduck)

05/15/2018 at 09:20 ē Filed to: None |  0 0

|  31 31 |

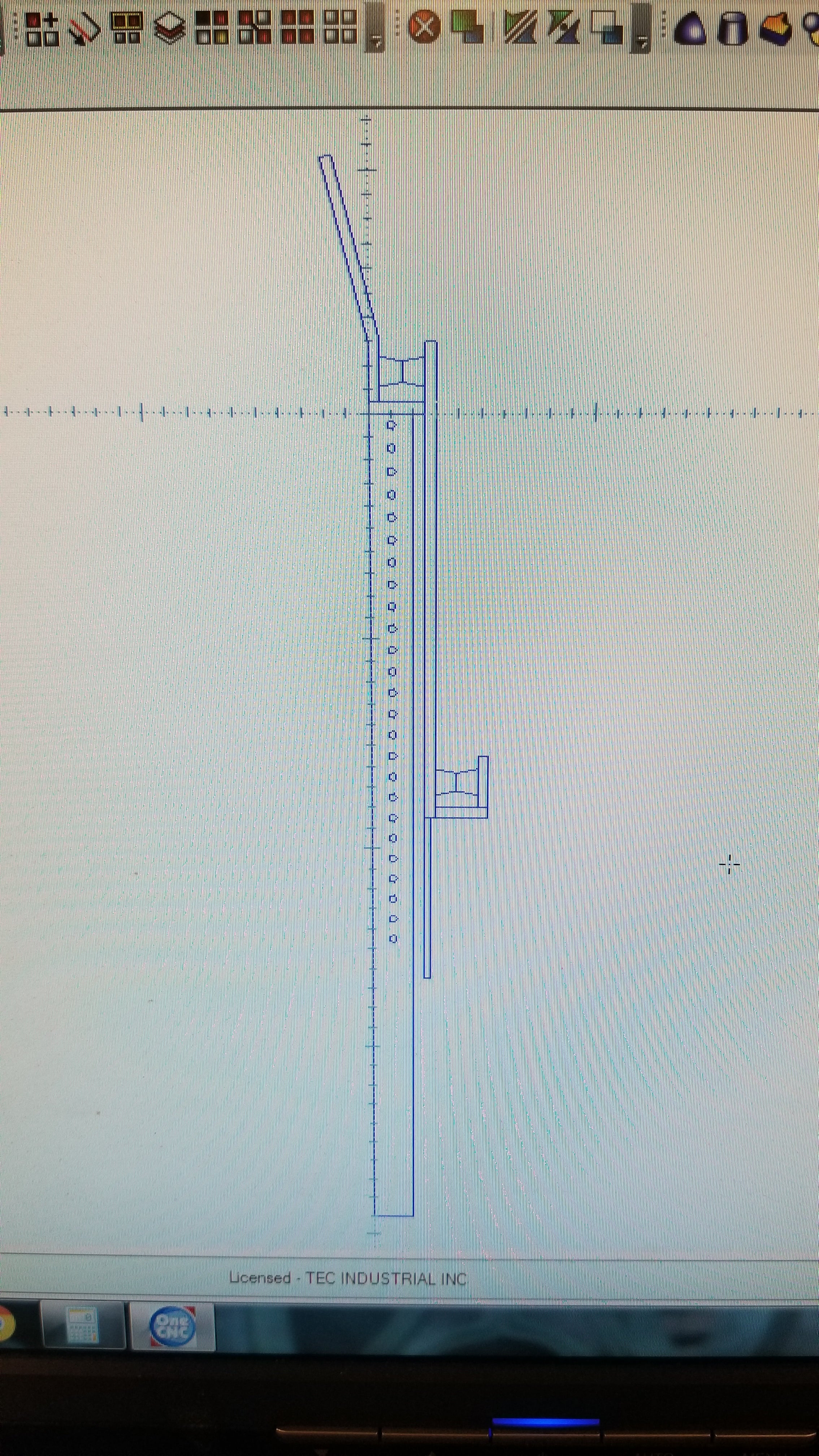

Calling all engineers. I have a materials question. I am working on building an IPF (International Powerlifting Federation) style combo rack. You can do squat and bench press with it.

My current issue is deciding on a material for a part in it.

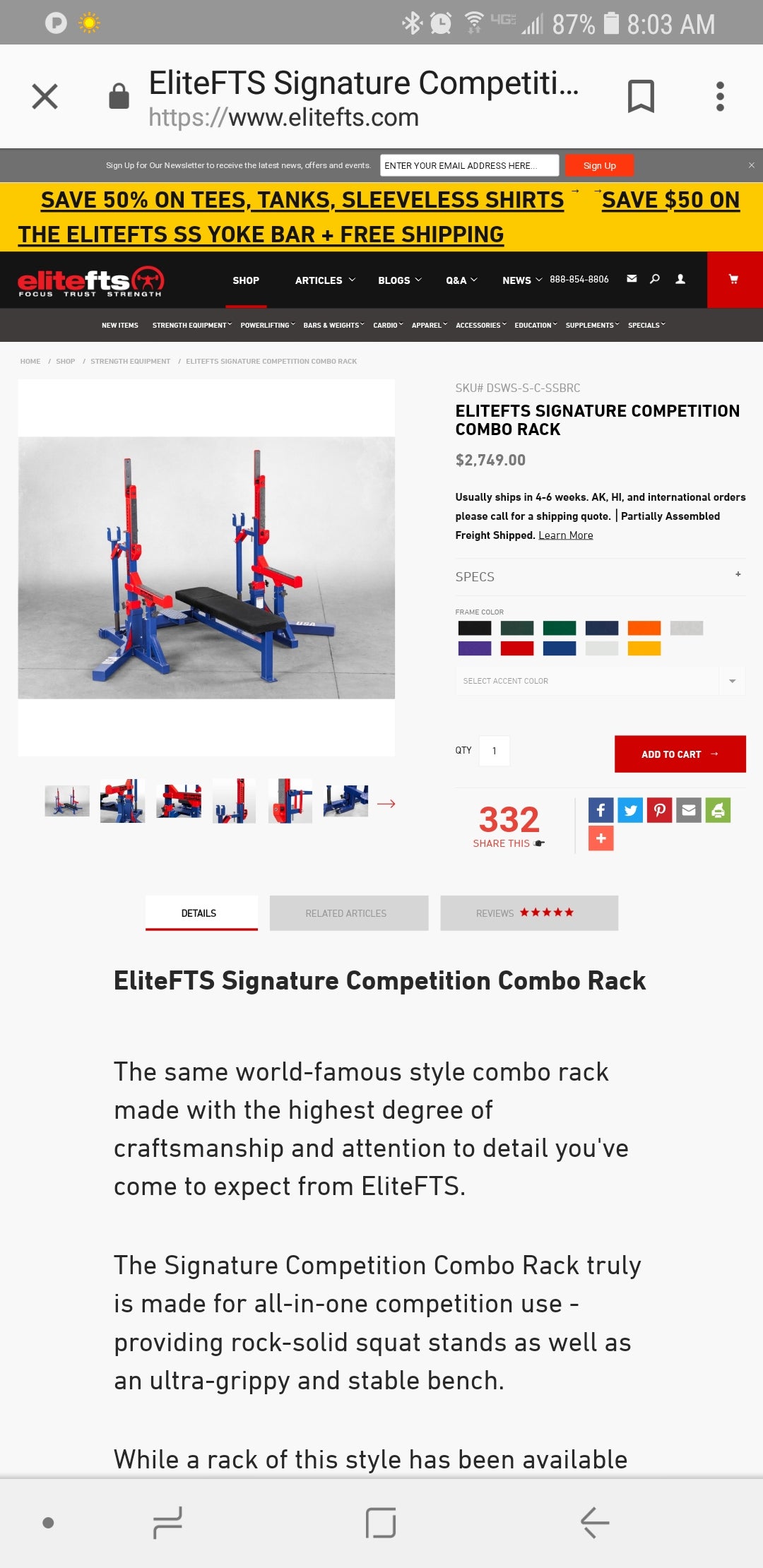

The combo rack that I am essentially copying.

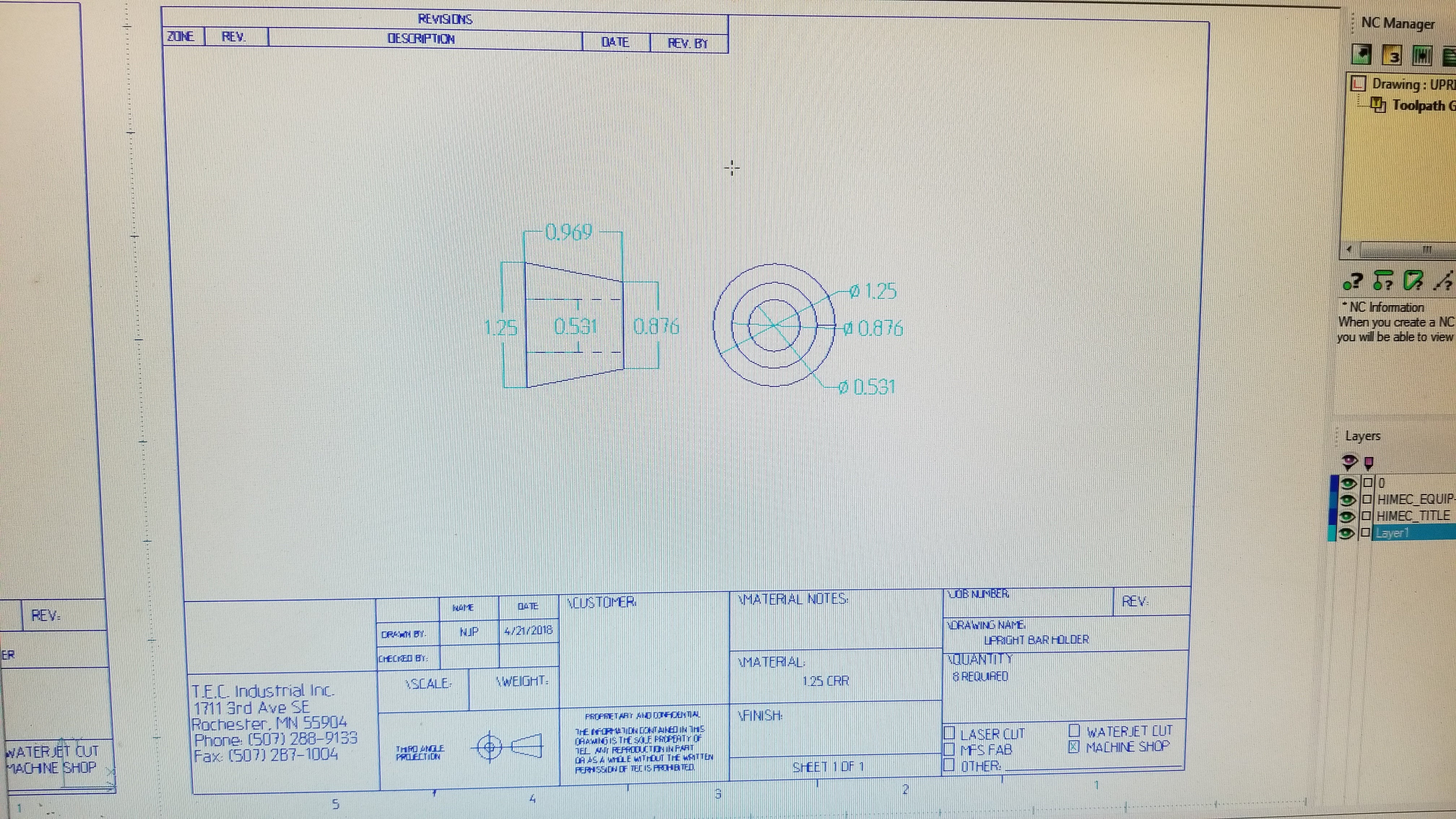

The tapered rollers in the above photo are my question. They appear to be made out of cold roll steel. I would like to make them out of a plastic to save the knurling on the bar. I am looking for suggestions on a plastic that would somewhat last if it exists.

Thank you all for any suggestions that you might have.

UPDATE

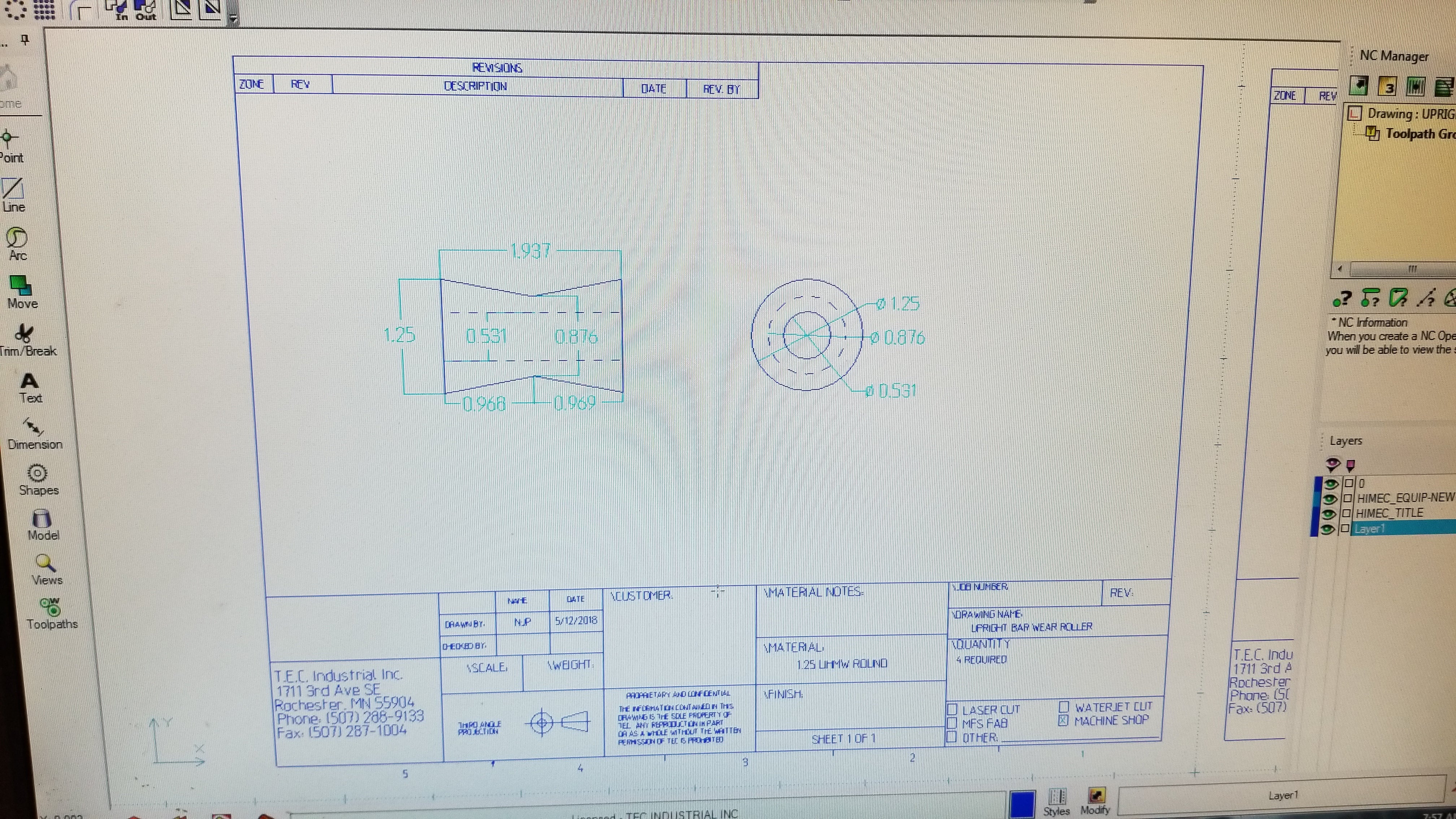

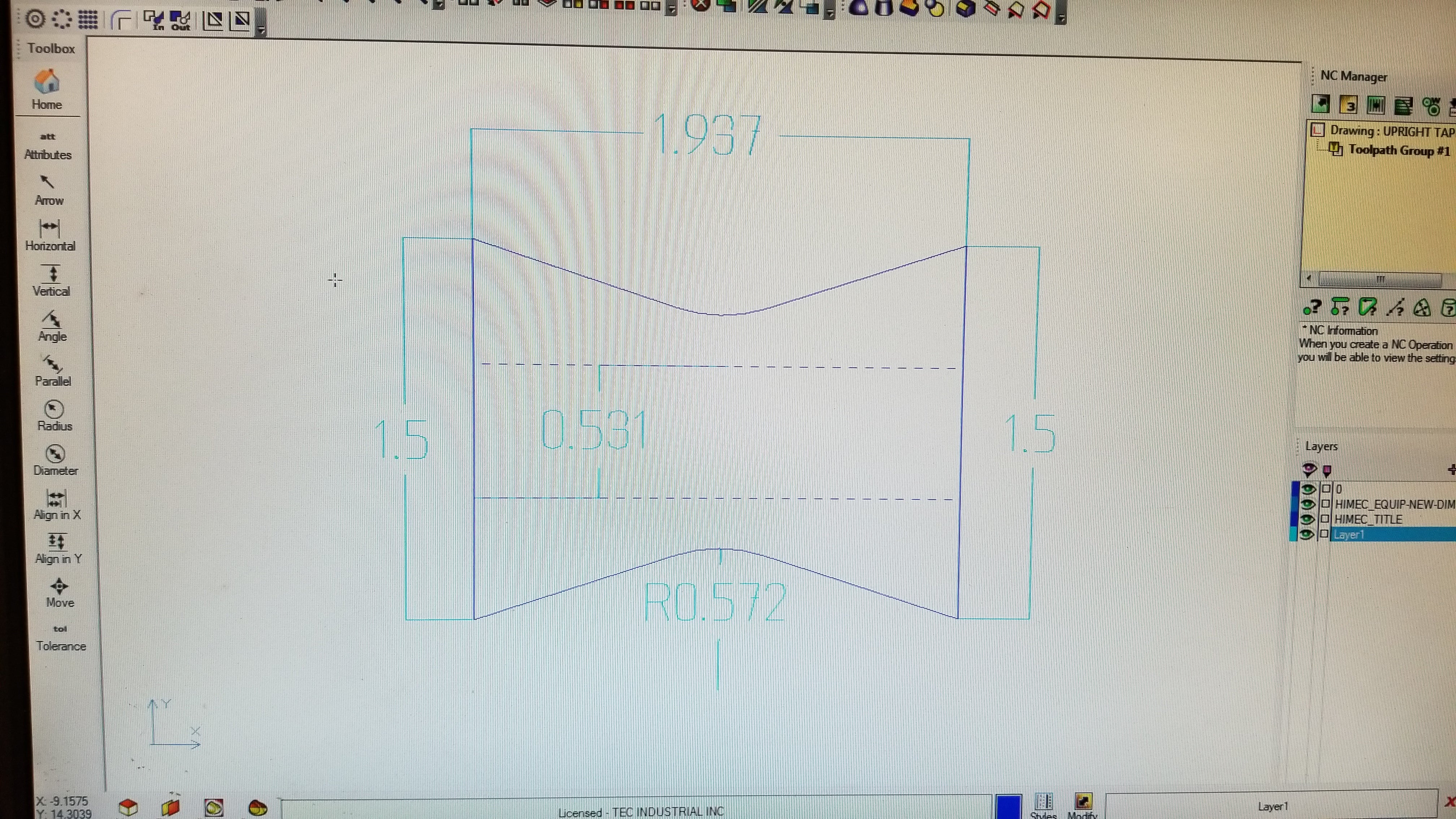

I have made a new drawing with some of suggestions I have received. Does this design seem better?

RamblinRover Luxury-Yacht

> Duck Duck Grey Duck FTMFW!

RamblinRover Luxury-Yacht

> Duck Duck Grey Duck FTMFW!

05/15/2018 at 09:57 |

|

I would say use an anchor roller replacement wheel:

https://www.marinedepotdirect.com/anchor-roller-replacement-wheels.html

Delrin, which is to say pretty hard nylon-like material. If you want something grippier and softer, try grinding down skateboard wheels. Urethane.

Iím trained as an engineer, but 90% of this kind of thing is knowing what exists off the shelf.

RamblinRover Luxury-Yacht

> Duck Duck Grey Duck FTMFW!

RamblinRover Luxury-Yacht

> Duck Duck Grey Duck FTMFW!

05/15/2018 at 09:58 |

|

Hereís one that might be urethane:

Duck Duck Grey Duck FTMFW!

> RamblinRover Luxury-Yacht

Duck Duck Grey Duck FTMFW!

> RamblinRover Luxury-Yacht

05/15/2018 at 10:07 |

|

Okay. I was originally thinking of using UHMW but I am not sure how far the knurling would eat through it. I understand itís a wear part, just donít want to be replacing it constantly. I spoke with a guy at my gym who happens to be a mechanical engineer and he mentioned that instead of a tapered design on the roller, change it to a radius.

Duck Duck Grey Duck FTMFW!

> RamblinRover Luxury-Yacht

Duck Duck Grey Duck FTMFW!

> RamblinRover Luxury-Yacht

05/15/2018 at 10:08 |

|

Also machining it is not a big deal. I has CNC lathe.

Ash78, voting early and often

> Duck Duck Grey Duck FTMFW!

Ash78, voting early and often

> Duck Duck Grey Duck FTMFW!

05/15/2018 at 10:09 |

|

Iím not an engineer but bro, I even lift.

To be honest, the knurling on the outer ends of the bar is only modestly useful for things like snatch-grip deadlifts (or snatches, snaturally!). To that end, I donít think wear and tear is a big issue. A steel of comparable hardness to the bar would be ideal.

Polyurethane would probably be fine, too, but would wear out and require periodic replacement.

Also maybe consider making the indentation closer to the exact diameter of an Olympic bar so it ďrolls into placeĒ rather than being pinched.

ITA97, now with more Jag @ opposite-lock.com

> Duck Duck Grey Duck FTMFW!

ITA97, now with more Jag @ opposite-lock.com

> Duck Duck Grey Duck FTMFW!

05/15/2018 at 10:24 |

|

Iím not engineer, but it seems like the answer you are looking for is found in a marine shop. https://www.easternmarine.com/em_store/rollers/

You can get them in both rubber and urethane. Considering the ones on my boat trailer have been in use with a 5500lbs boat and exposed to the elements outdoors since 1995 and are still in serviceable condition, I canít imagine they wouldnít hold up to being used on gym equipment.

Duck Duck Grey Duck FTMFW!

> Ash78, voting early and often

Duck Duck Grey Duck FTMFW!

> Ash78, voting early and often

05/15/2018 at 10:24 |

|

Well thatís two people that have mentioned that idea so that might be happening.

RamblinRover Luxury-Yacht

> Duck Duck Grey Duck FTMFW!

RamblinRover Luxury-Yacht

> Duck Duck Grey Duck FTMFW!

05/15/2018 at 10:26 |

|

Basically, my thought is that a bow roller, since itís able to have a rope rolling through its smallest diameter notch constantly, is not only wear resistant enough but also strong enough. It will retain the bow of a boat in place on a trailer and forcibly center it up (what they get used for other than anchors - drawing a boat up with the anchor line onto a trailer.

My thought was, if an existing part will cost not much over $10, you can even afford to stock spares.

nerd_racing

> Duck Duck Grey Duck FTMFW!

nerd_racing

> Duck Duck Grey Duck FTMFW!

05/15/2018 at 10:26 |

|

I was also going to suggest UHMW to use. We cnc machine parts out of it at work and it is a bearing type material. †

Duck Duck Grey Duck FTMFW!

> RamblinRover Luxury-Yacht

Duck Duck Grey Duck FTMFW!

> RamblinRover Luxury-Yacht

05/15/2018 at 10:39 |

|

I agree with your logic. My only other concern is the twisting motion of the barbell. When I personally go to grab the barbell, I twist it. I asm not sure how Delrin would handle this. The knurling on my barbell is very aggresive. These bow rollers wouldnít experience this kind of wear I believe. I do like the thought of just buying an off the shelf part of I can find one that confirms to the constraints of where it is located.

Duck Duck Grey Duck FTMFW!

> nerd_racing

Duck Duck Grey Duck FTMFW!

> nerd_racing

05/15/2018 at 10:43 |

|

We also use it all the time at work. My biggest concern is the twisting motion that I impart on the barbell. Especially when loaded with weight.

RamblinRover Luxury-Yacht

> Duck Duck Grey Duck FTMFW!

RamblinRover Luxury-Yacht

> Duck Duck Grey Duck FTMFW!

05/15/2018 at 10:48 |

|

Well, ropes twist under tension, so itís not a completely foreign thing - also, Delrin is used for bearings. Worst thing they can do is wear out, right?

TorqueToYield

> Duck Duck Grey Duck FTMFW!

TorqueToYield

> Duck Duck Grey Duck FTMFW!

05/15/2018 at 10:51 |

|

Itís hard to get anything to Ďeat throughí UHMW. Itíll just deform a bit at the point where it touches the knurling then spring back a bit when the load is released. Thatís why its so resiliant.

That said I would try urethane first in a hard durometer. UHMW is really great for sliding and friction but without those motions I think urethane would stand up better to the weight and static loads. At some point plastic material selection becomes Ďtry it and see what happensí.

Duck Duck Grey Duck FTMFW!

> TorqueToYield

Duck Duck Grey Duck FTMFW!

> TorqueToYield

05/15/2018 at 11:02 |

|

I am worried about twisting of a loaded barbell on the plastic. The aggressive knurling on powerlifting barbells is nice to nothing. When I grab the bar I twist/rotate it. That is my biggest concern. I may just end up trying some UHMW. I could make some samples and try them on the already built racks and see how long they last.

Duck Duck Grey Duck FTMFW!

> RamblinRover Luxury-Yacht

Duck Duck Grey Duck FTMFW!

> RamblinRover Luxury-Yacht

05/15/2018 at 11:12 |

|

True. Just donít want it to wear it quickly. I think I may just make a few different prototypes and see how well they wear. I can give them to the gym to test them out.

Duck Duck Grey Duck FTMFW!

> Ash78, voting early and often

Duck Duck Grey Duck FTMFW!

> Ash78, voting early and often

05/15/2018 at 11:39 |

|

I have updated this post with a new drawing at the bottom. I think itís more along the lines of what you are talking about. Please let me know.

Ash78, voting early and often

> Duck Duck Grey Duck FTMFW!

Ash78, voting early and often

> Duck Duck Grey Duck FTMFW!

05/15/2018 at 11:44 |

|

Yes! Er, YAAASSSSS.

That might even be patentable.

Duck Duck Grey Duck FTMFW!

> Ash78, voting early and often

Duck Duck Grey Duck FTMFW!

> Ash78, voting early and often

05/15/2018 at 11:55 |

|

Lol maybe. Awesome thanks for your input on that. I think itís a better design as well.

Ronny P. Stiggs

> Duck Duck Grey Duck FTMFW!

Ronny P. Stiggs

> Duck Duck Grey Duck FTMFW!

05/15/2018 at 11:58 |

|

I donít even have my degree yet, so anyone can correct me if they like, but Delrin/Acetal is really tough stuff and has a really smooth, resistant finish if you have some that is available to you.

Ash78, voting early and often

> Duck Duck Grey Duck FTMFW!

Ash78, voting early and often

> Duck Duck Grey Duck FTMFW!

05/15/2018 at 12:00 |

|

Sure thing...Iím secretly an industrial designer, I just didnít get the education necessary to do it :D

The only very minor drawback would be cost ó milling out a single complex piece on a lathe vs pushing two simpler pieces together (over a pin?) might add a bit to the cost, but at this price range it probably wonít matter.

Duck Duck Grey Duck FTMFW!

> Ash78, voting early and often

Duck Duck Grey Duck FTMFW!

> Ash78, voting early and often

05/15/2018 at 12:13 |

|

It is going on a 1/2 shoulder bolt. Once I get a design figured out I can figure out a price per part.

Duck Duck Grey Duck FTMFW!

> RamblinRover Luxury-Yacht

Duck Duck Grey Duck FTMFW!

> RamblinRover Luxury-Yacht

05/15/2018 at 12:15 |

|

If I decide to make some prototypes out of Urethane, what would be a good durometer?

Duck Duck Grey Duck FTMFW!

> TorqueToYield

Duck Duck Grey Duck FTMFW!

> TorqueToYield

05/15/2018 at 12:25 |

|

Sorryi asked RamblinRover when I meant to ask you, what would be a good durometer to try?

RamblinRover Luxury-Yacht

> Duck Duck Grey Duck FTMFW!

RamblinRover Luxury-Yacht

> Duck Duck Grey Duck FTMFW!

05/15/2018 at 12:40 |

|

High end Shore A, I guess. I think the worst for wear would be anything that is not only soft enough to imprint from the knurling, but just hard enough to shear material instead of give. So, I think the best options are harder than that critical point and (maybe) softer.

TorqueToYield

> Duck Duck Grey Duck FTMFW!

TorqueToYield

> Duck Duck Grey Duck FTMFW!

05/15/2018 at 14:31 |

|

Urethane? I would try the hardest you can get first. Seems like 95A is available on McMaster. https://www.mcmaster.com/#8695k177 †UHMW only comes in one hardness AFAIK.

Censored

> Duck Duck Grey Duck FTMFW!

Censored

> Duck Duck Grey Duck FTMFW!

05/15/2018 at 15:30 |

|

Nylatron will be a good plastic for this application. UHMW will distort under heavy point weight and the knurling of the bar will chew into it as it is fairly soft. Nylatron is very hard and durable but $$.

Duck Duck Grey Duck FTMFW!

> TorqueToYield

Duck Duck Grey Duck FTMFW!

> TorqueToYield

05/15/2018 at 16:01 |

|

I think I will make up some pieces it off UHMW first because I have that on hand.

Future next gen S2000 owner

> Duck Duck Grey Duck FTMFW!

Future next gen S2000 owner

> Duck Duck Grey Duck FTMFW!

05/16/2018 at 09:45 |

|

We use 60-70 for seals on gates. I would stay above 60. Still has some give but will hold up to the pressure from the bar.

Future next gen S2000 owner

> Duck Duck Grey Duck FTMFW!

Future next gen S2000 owner

> Duck Duck Grey Duck FTMFW!

05/16/2018 at 09:48 |

|

People have been suggesting polyurethane or uhmw but what about brass? It is a soft metal and will take the wear over a harder steel, wonít require replacement. Will be hard as hell to find the material to machine I would think.

Duck Duck Grey Duck FTMFW!

> Future next gen S2000 owner

Duck Duck Grey Duck FTMFW!

> Future next gen S2000 owner

05/16/2018 at 12:50 |

|

Maybe, will do some checking. Thanks for the suggestion.

Duck Duck Grey Duck FTMFW!

> RamblinRover Luxury-Yacht

Duck Duck Grey Duck FTMFW!

> RamblinRover Luxury-Yacht

05/17/2018 at 12:14 |

|

What about brass or bronze? Any thoughts on either of them?